2020/11/27 0:00:00

2020/11/27 0:00:00 5755

5755

Recently, the Linde R&D Technology Center and Remote Control Center in Shanghai held a media open day event. China Hydrogen Energy Network was invited to participate and visited various laboratories of the R&D center.

Visit link

During the visit, we saw the effects of different laser gas cutting sections, saw the quick-freezing efficiency of intelligent quick-cooling equipment, tasted delicious homemade liquid nitrogen ice cream, and learned about the liquid nitrogen artificial freezing technology used in large-scale civil engineering. , Plastic foaming technology and emission control equipment widely used in the chemical and pharmaceutical fields, as well as surfacing equipment for waste gas combustion chambers.

▲Laser cutting equipment

The cutting process is very fast, the cutting quality is also quite high, and the surface of the material is smooth and clean without any oxidation.

▲Liquid nitrogen artificial frozen soil technology demonstration sand table

▲Laser surfacing equipment

Linde can simulate the process in the laboratory according to the customer's different processes and materials, and provide customers with the best welding mixed gas solution. At the same time, it can also save materials and reduce costs.

Interactive communication link

China Hydrogen Energy Network had an on-site exchange with Dr. Zhu Heng, the head of applied technology research and development in the Asia-Pacific region. The following is the interview record:

China Hydrogen Energy Network: "Hello, I am a reporter from my country Hydrogen Energy Network. Our country is striving to achieve the goal of carbon neutrality by 2060. I would like to know about Linde’s efforts in this regard, especially in the field of hydrogen energy, in the future. Strategic considerations in R&D or technology during the year."

Dr. Zhu Heng: "Hydrogen energy is a tens of billions-dollar business for Linde, and Linde also attaches great importance to this. Linde, as a gas company with a long history, has a long history in the production, storage, and transportation of hydrogen energy. In terms of terminal applications, including cost control, many technologies have been accumulated in each link. In addition, hydrogen energy, as a gas, cannot be transported across seas and other long distances. From production to application, especially the application side, it must be localized. Localization is also an inevitable way for Linde as a multinational company. In every aspect, Linde has made localized layouts, such as:

Linde has cooperation with local companies such as CNOOC and Guodian.

As an energy source, hydrogen energy is still in the early stages of development. The cost of green hydrogen has yet to be reduced to support its popularity. One of Linde’s joint ventures, ITM Linde Electrolysis Co., Ltd., is committed to green hydrogen production, water electrolysis hydrogen production, and research and development of hydrogen production technology to reduce hydrogen production costs.

In September, Linde and Dalian Bingshan established a joint venture company, which marked the beginning of localization of Linde's hydrogen refueling technology (hydrogen refueling station operation management, core equipment ion compressor, etc.).

Linde attaches great importance to hydrogen energy. We believe that this is an industry that can be continued and can be profitable and win-win. For the localization of hydrogen energy, Linde has also taken some actions and looks forward to longer-term stable development. "

Mr. Tao Wang, Head of Commercialization of Applied Technology in the Asia-Pacific Region, added to Dr. Zhu Heng’s answer:

"China, including other countries, is developing hydrogen energy as a national strategy. An important reason is that in addition to the non-renewable fossil fuels, energy research is more out of environmental protection. Our development of hydrogen energy must be based on On the basis of environmental protection, if it deviates from the original intention, in fact, hydrogen energy is largely meaningless. If it is at the cost of adding new emissions, then hydrogen energy is not developing in a healthy way. Therefore, truly healthy hydrogen should first pay attention to environmental protection. , The second is to solve the safety problem, and then the economy. Linde hopes that the industry can develop healthily in the future, and also hopes that the country and the government will give more guidance.

The hydrogen energy industry needs to be highly specialized, because the operation of hydrogen requires very high quality and cannot be at the expense of safety. Linde’s advantage is based on the use of hard-core technology for hydrogen production for many years, such as liquid hydrogen technology, including the core equipment of some hydrogen refueling stations. Linde can play an important role in the development of hydrogen energy in China, especially in the early stages.

Another very important point is that if hydrogen energy as an industry wants to develop soundly, it must vigorously develop downstream applications, so that it can be sustainable and an ecosystem can be established. Therefore, from the perspective of Linde R&D, more attention will be paid to the application side. Linde is currently cooperating with some foreign customers in application aspects. For example, some large steel companies are doing hydrogen energy metallurgy to reduce iron ore, including the use of hydrogen as fuel for heating furnaces, instead of carbon and fossil fuels. In the recent first half of the year, Linde has also cooperated with some European companies to use hydrogen for heating in the heating furnace, and no longer use natural gas. Many foreign steel companies have put forward goals, such as completely eliminating carbon emissions by 2030 or 2035. I believe that Chinese steel companies, especially some leading companies, are actually planning to gradually develop their production capacity towards green manufacturing. Therefore, we have many opportunities in this regard. Linde can work with domestic partners to build a sustainable hydrogen energy industry ecology. "

China Hydrogen Energy Network: "The hottest topic now is about the epidemic. The environment in mainland China is relatively stable, but there are many uncertain factors in the international situation. Will this become Linde’s direction of part of the technology, including the production of core equipment,? A starting point for China's transfer?"

Dr. Zhu Heng: “In terms of resource input, Linde’s headquarters has given great support to the R&D team and R&D projects in the Asia-Pacific region. In addition, Linde’s core business air separation and other core equipment localization process, long before the epidemic It’s been going on all the time. The epidemic will certainly help some localization processes, but the overall localization trend has already begun in Linde. The epidemic is also a development opportunity for Linde. Linde operates in major regions such as the Americas. , Europe, and the Asia-Pacific, all coincide to use green economy as one of the driving forces of economic recovery. Europe, the United States, and China are all investing heavily in hydrogen energy, which has brought some new issues to Linde’s research and development. It has become an opportunity for Linde’s development."

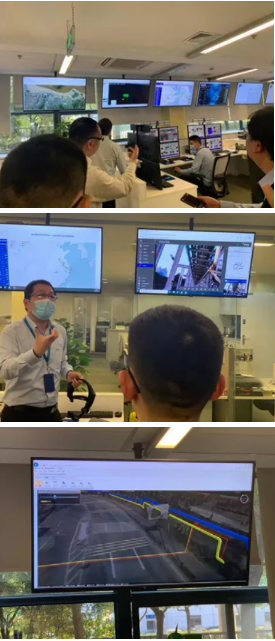

About the remote control center

According to the person in charge of the site, the establishment of Linde's remote operation center is the prerequisite and basis for the development of Linde's fully automated digital operation system management. Linde's remote control center started in 2008 and is the first domestic gas company with air separation remote operation capabilities. After 12 years of development, there are 168 devices in the operation center that can be connected to monitor, especially in a large number of unmanned factories, which are operated and operated like this on weekends and nights, and can even be globally interconnected.

Remote operation, efficiency monitoring and the application of digital technology are currently the three major tasks of Linde's remote operation center. The remote control center mainly includes air separation device, digital platform (pipe network digital map, device database, efficiency analysis expert system, etc.), smart glasses application, liquid automatic filling system, etc. The person in charge of the site said that Linde will develop and apply more digital products.

China Hydrogen Energy Network also learned from the Linde site leader that explosion-proof equipment is used in the control center. The system will calculate based on changes in gas flow and pressure. If abnormalities occur, the system will immediately alarm. Even if hydrogen leaks out colorless and odorless, the staff can immediately know the location of the accident by judging the equipment parameters through machine learning.

According to the person in charge of the site, he believes that the future development trend of hydrogen refueling stations is also remote control, through image recognition, ultrasound, infrared and other technologies to minimize human intervention.

About Linde

Linde is one of the world's leading industrial gas and engineering companies with sales of 28 billion U.S. dollars (25 billion euros) in 2019. Every day, we are committed to fulfilling our corporate mission-lean and high yield, benefiting the world, with high-quality technology, services and solutions to help customers achieve greater success, while protecting our planet and making it sustainable .

Linde's end markets cover many industries, including aerospace, chemicals, food and beverages, electronics, energy, healthcare, manufacturing, and primary metals. The industrial gases produced by Linde are used in various fields-from oxygen used in hospitals to high-purity and specialty gases used in the electronics industry to hydrogen used in clean energy. At the same time, Linde also provides a series of cutting-edge gas treatment solutions to support customer business development, improve efficiency and reduce carbon emissions.

About Linde Greater China

Linde Greater China is headquartered in Shanghai, has approximately 2,600 employees across the country, and operates more than 100 sites. Its business footprint covers North China, East China, South China and Western China. Linde is one of the leading gas supply and engineering companies in China. It has established long-term partnerships with many leading customers in the chemical, petrochemical, metallurgical, manufacturing, electronics, food and medical industries, and has established long-term partnerships with high-quality technology and services. And solutions to help customers achieve greater success.